Posted on 26 Feb 2019

At the Paris Climate Summit in 2015, the world governments agreed to keep the global temperature rise under 2°C , if possible1.5°C, by the end of this century to avoid the worst impacts.

The planet’s resource is finite, and the European Union who consistently takes a proactive role in promoting environmental sustainability concluded that effective management of the resource and recycling, as well as the eco-friendly products will bring a positive impact on the economy. Environmental sustainability is not just a boutique concept anymore – it has now become a matter of essentiality, our survival.

Producing zero environmental impact in our everyday life is for the benefit of all life on earth. The plastic disaster triggered across all corners of the globe is already changing our lives – at major coffee shops, take-out cups are discouraged, and the plastic straws are disappearing. More consumers are voluntarily backing this trend, and as a result, industries are changing their policies.

Although it seems there is no direct connection between the steel industry and eco-friendly practice, POSCO is also stepping up its efforts to promote sustainability. Why is a steel company like POSCO trying to go green? POSCO Newsroom reports.

Steel is fully recyclable. Countless other materials get buried or incinerated after use, but steel is rarely discarded and is actually recycled. Since it’s magnetic, steel is easy to separate even when it’s mixed with other waste materials.

For example, recycling one steel can save energy equivalent to that of one washing-machine cycle and one-hour of TV-watching.

Steel is not only recyclable but it also dissolves in high heat to produce high-quality steel. Manufacturing steel this way can save 62% of the energy compared to the conventional manufacturing method, while significantly reducing carbon dioxide emissions.

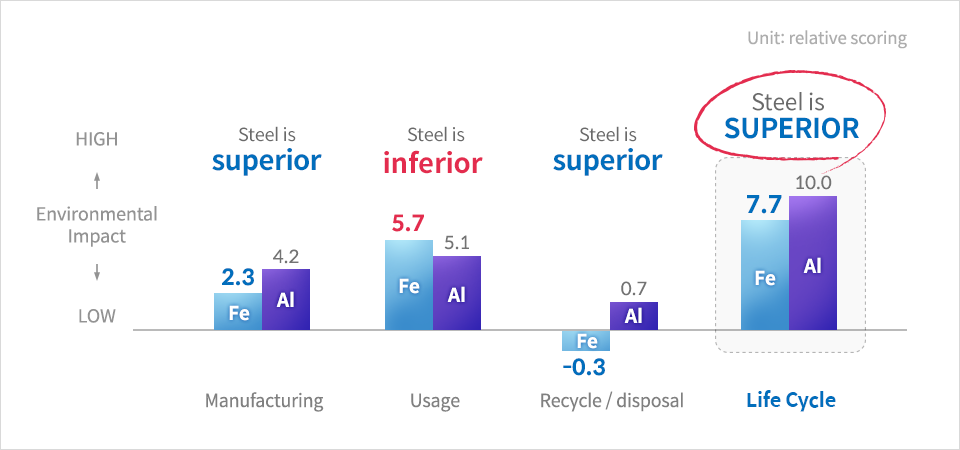

▲Environmental impact: steel vs aluminum (Source: POSRI estimate based on figures from worldsteel, NSSMC & JISF)

Aluminum can be recycled, but it’s nearly impossible to remove impurities, making it difficult to reuse. When applying the Life Cycle Assessment approach, steel is much more sustainable than aluminum.

One of the quintessential images of a steel mill is that of liquefied iron ‘boiling’ in the furnace. Because steelmaking demands lots of energy, it is hard to associate environmental sustainability with the material. For this very reason, however, the industry is making an extra effort to create an eco-friendly business practice. Technological development effort such as POSCO’s ironmaking technology, FINEX, is one such example.

POSCO’s proprietary technology makes steel stronger and lighter, as is the case with its Giga Steel. Cars made of Giga Steel can help reduce greenhouse gas emissions by boosting fuel efficiency when driving.

POSMAC is a coated steel sheet that’s highly corrosion-resistant. It has a longer service life in severe corrosive environments with chlorine, strong alkaline, high temperature, and humidity. When applied to marine-aquamarine, solar, and wind power tower, the corrosion is minimized, which in turn increases its use period thereby reducing the needs for reconstruction.

POSCO is also taking a proactive role in minimizing the pollutants generated during the steel production. While producing one-ton of steel, approximately 600-700kg of byproducts are made. With 98.4% of such byproducts recycled within and out of POSCO, the recycling rate is superb.

The potential of steel is endless. Steel accompanied the humanity throughout the history, is getting lighter than ever. The steel cans we use today are about 30% thinner than those made in the 1980s. Energy consumption for producing one ton of steel production is steadily declining.

Steel is used in a variety of ways, ranging from light industry products such as steel can for food and beverages, to shipbuilding and other heavy industry products. Steel is also excellent for food preservation as well as for preventing surface corrosion for ships, etc.

Cars became lighter, and reducing green gas house also became more viable, through high-efficiency steel products like High Strength Automotive Steel with improved fuel efficiency. An electrical steel sheet with low iron loss for high-efficiency contributes to the energy efficiency of motors and transformers. In 2017, high-efficiency steel helped reduce greenhouse gas emissions by 614,000 tons.

Also during 2017, granulated blast furnace slag, one of the by-products from steelmaking process, contributed to reducing 8.6 million green gas emission – by being recycled as a cement substitute.

As the post-Paris Climate Summit paradigm prioritizes environmental sustainability, the business leaders are following the suit, expanding environmentally friendly business practice across its diverse sectors. The reason why companies are opting for environmental sustainability is not just for the sake of public interest – the global community is setting the tone for environmental sustainability. The consumer demand for eco-friendly products considering life cycle assessment is also increasing.

Considering environmental impact, versatile, convenient and recyclable steel is expected to draw more attention in the future both from the industry and consumers.