Posted on 03 Feb 2026

Hyundai Steel Co., South Korea’s second-largest steelmaker, plans to mass-produce a newer, upgraded automotive steel in the first quarter at the earliest, betting that lighter and stronger materials will help it expand deeper into the global car market.

The steelmaker on Monday said it has completed development of its third-generation advanced high-strength steel (AHSS) for vehicles and is now testing the product with customers, including affiliates Hyundai Motor Co. and Kia Corp.

Commercial production is expected to begin as early as March, the company said.

With the new product, Hyundai Steel hopes to raise the share of auto steel sales to global automakers beyond Hyundai Motor and Kia to 30% by 2030, up from 19% in 2024. The figure stood at just over 10% in 2018.

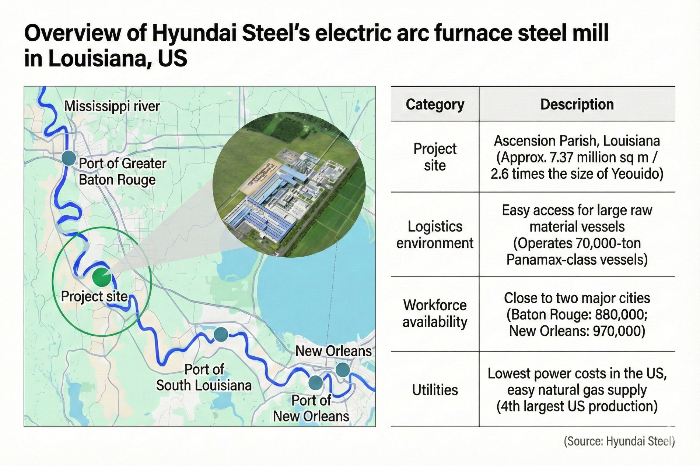

The company is also pinning high hopes on its first US steel mill in Louisiana, scheduled to break ground in the third quarter, as a cornerstone of its global expansion strategy.

LIGHTER STEEL FOR ELECTRIC VEHICLES

Hyundai Steel said the new product is particularly well-suited for electric vehicles, where automakers face growing pressure to cut weight while meeting stricter safety and design requirements.

Automotive steel has long involved a trade-off between strength and formability. Increasing strength typically makes steel harder to shape, while improving formability often comes at the expense of durability.

Hyundai Steel said its third-generation advanced high-strength steel narrows that gap.

The steel has a tensile strength of about 1.2 gigapascals (GPa), compared with roughly 1.0 GPa for earlier grades, while offering more than a 50% improvement in elongation, making it easier to mold into complex shapes.

An auto industry official said the material is more than 10% lighter than conventional ultra-high-strength steel, a key advantage for electric vehicles, where weight reduction can extend driving range without compromising crash safety.

Company executives said the steel will initially be supplied to Hyundai Motor and Kia, with plans to broaden sales to global automakers as testing progresses.

LOUISIANA PLANT ANCHORS US STRATEGY

Image by Sookyung Seo, Gemini (Nano Banana)

A key pillar of Hyundai Steel’s global quest is a new electric arc furnace steel mill, which will be built in Louisiana, designed to produce 2.7 million tons of steel a year.

The plant is scheduled for completion in the first quarter of 2029 and will produce the third-generation AHSS steel, initially supplying US factories operated by Hyundai Motor Group's auto-making sibling companies.

The facility is part of a broader $5.8 billion US investment announced last year by Hyundai Motor Group, aimed at localizing production, cutting logistics costs and insulating operations from tariffs and other trade restrictions.

By producing steel inside the US, Hyundai Steel aims to reinforce ties with US automakers and position itself as a more competitive supplier as Washington tightens trade defenses.

The US currently imposes tariffs of up to 50% on steel imports from South Korea.

Hyundai Steel last week reported an operating profit of 219.2 billion won ($151.3 million) for 2025, up 37% from a year earlier, while sales fell 2.1% to 22.73 trillion won.

The company cited a slowdown in construction demand and rising protectionism in global trade for weaker sales, while operating profit improved on cost controls and product mix.

Source:The Korea Economic Daily Global Edition