Posted on 20 May 2025

Morning Brief: Promoting energy efficiency measures in the Indian iron and steel sector is of the greatest importance in the short-term, especially for the BF-BOF route, in driving energy transition and reduction of carbon emissions. According to the Ministry of Steel (MoS), the high energy intensity of the sector is evident from the fact that energy constitutes 20-40% of steels total manufacturing cost. The sectors overall energy consumption is over 70 million tonnes (mnt) of oil equivalent per annum.

Besides the existence of a mix of old and new production technologies, the inadequate adoption of technologies for harnessing waste heat/energy due to constrains and increased dependency on solid fossil fuels results in overall higher energy consumption and CO2 emissions.

"Energy consumption varies widely in the Indian iron and steel industry, and it is attributed to several factors such as the route of production, technology, quality of raw materials, size and vintage of the plant, and operational practices. While some of the plants have upgraded their technology and are operating at higher energy efficiencies, other units are still using old equipment resulting in high energy consumption and emissions," as per MoS.

Best available technologies

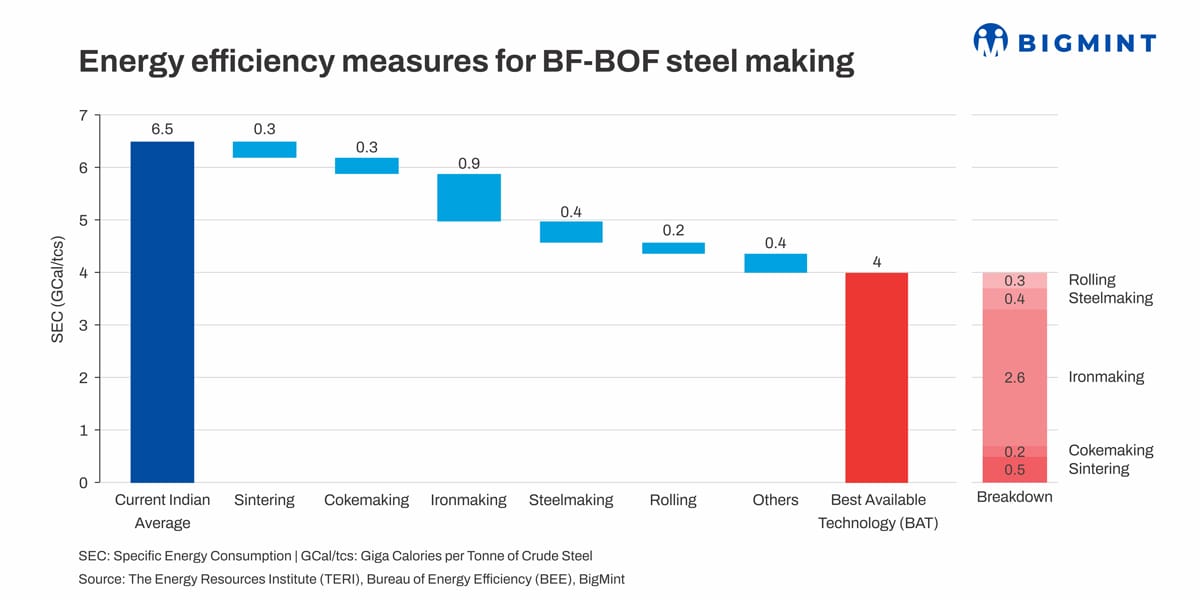

The average specific energy consumption of the BF-BOF route is 6.0-6.5 Gcal/tcs (giga calories per tonne of crude steel), and the average specific energy consumption of the inefficient plants is 7.1 Gcal/tcs whereas the global average specific energy consumption is in the range of 4.5-5.0 Gcal/tcs.

However, there is potential for reducing the specific energy consumption of Indian BF-BOF plants from the current level of 6.5 Gcal/tcs to 4.5 to 5.0 Gcal/tcs through the implementation of best available technologies (BATs) in different sub-processes.

Some examples of BATs are sinter waste heat recovery for steam generation, coke dry quenching (CDQ) and stamp charging technologies, top pressure recovery turbine (TRT), pulverised coal injection (PCI) in blast furnace, dry gas cleaning plant with bag filters for BFs and BOFs, hot stove waste heat recovery, regenerative burner in reheating furnace, etc.

PAT scheme

The average CO2 emission intensity of the Indian steel industry has reduced from around 3.1 tonne of CO2 per tonne of crude steel in 2005 to around 2.55 t of CO2 in 2024. The iron and steel industry has been adopting the best available, state-of-the-art technologies for optimisation of production processes, harnessing waste heat/ energy, and catching up with the global benchmarks by enhancing productivity and energy efficiency.

The Perform, Achieve and Trade (PAT) scheme covers 100% BF-BOF and EAF units in the country. It has been instrumental in driving energy efficiency efforts in the Indian iron and steel industry as the sector achieved total energy savings of 6.137 mnt of oil equivalent up to Cycle V (2021-22), exceeding the targeted energy savings of 4.575 mnt of oil equivalent and contributed to 24% of total energy savings achieved in the country.

Outlook

According to the MoS, Industry 4.0 plays a pivotal role in driving decarbonisation and improving energy efficiency within the steel industry. By integrating digital technologies such as the Internet of Things (IoT), artificial intelligence (AI), machine learning (ML) and advanced analytics, steel manufacturers can optimise processes to reduce carbon emissions and enhance energy utilisation.

Furthermore, Industry 4.0 facilitates the implementation of energy management systems that optimise the overall energy usage across the steel production process. In essence, Industry 4.0 serves as a catalyst for decarbonisation and energy efficiency in the steel industry by enabling data-driven decision-making, process optimisation, and the deployment of innovative technologies.

The MoS has estimated that the total capex requirement for implementation of BATs in the integrated steel sector is INR 12,711 crore. The action plan drawn up has as its key objectives the adoption of BATs and energy efficiency technologies, energy benchmarking and audits, as well as extending the coverage of the emerging carbon credit trading scheme (CCTS) to cover all the major steel plants in the country.

Source:BigMint