Posted on 12 Dec 2018

Technology and equipment are important to reach high perfor mance and to remain competitive, and, of course, methodology is important to analyse the situation, identify potentials and utilise them, but BSW considers the people working in the company as the most important asset. This is why BSW put in a lot of effort and investment into its workforce.

Safety Culture

At a very early stage, BSW started to take care of its personnel. Driven by tough German safety regulations, the management recognised that health and safety Iead to well-motivated employees and a long commitment to the company. Nevertheless, for decades, BSW’s strategy

still had been dominated by values such as:

- Production frst.

- Everybody is responsible for themselves.

- Safety costs money and wastes time.

But today the environment has changed, e. g. different expectations and attitude of employees, new legal obligations. So BSW had to change its mind-set about health and safety frst. The goal was for all BSW directors, managers and supervisors to talk about safety in order to fnd out what happens under the “water surface” of the “problem iceberg”

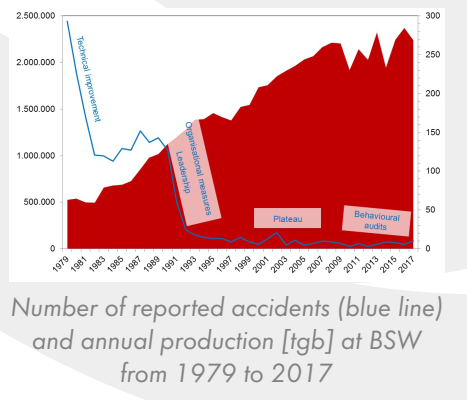

After changing the mind-set and identifying causes for accidents, BSW has managed to reduce the risk of accidents over the past

few years by using the “TOP” principle:

T – Technical improvement

For example, to get people to a safe distance from hazards, in 2012, BSW and BSE developed the MultiROB for temperature measurement, sampling and camera control of refractory.

O – Organisational measures

Setting clear safety standards, described and fxed in standard operating procedures (e. g. safe ways in production areas).

P – Person-related measures

Mandatory wearing of personal protective equipment, behavioural audits, instructions accompanied with continuous training.

Using the “TOP” principle means that one must always Iook for a technical improvement before using organisational or – at the very end – person-related safety measures. BSW uses this clear hierarchy for safety improvement and always aims for a

technical solution frst.

But still, more than 80 % of all accidents happen because people behave in an unsafe manner, either by error or by violation of safety guidelines. Therefore, the company has to learn from each reported near miss, unsafe act or unsafe condition in order to prevent accidents.

Education and Training

At the beginning of the 1980s, only 35 % of BSW’s workforce had been skilled, and only a little training had been offered to the workforce. As a consequence, BSW’s productivity had been on a fairly low level. Therefore, the owners of the Badische Group decided to launch an extensive

training programme:

- First, in 1979, a training department was set up (as a sub-department of Human Resources).

- Second, in 1983, a critical mass of its workforce was sent to a Japanese steel maker (Kimitsu Works /Nippon Steel Corporation; regarded as “benchmark” at that time) for a detailed know-how and technology exchange.

- Third, in 1989, the Badische Group established the BAG Training Centre, an independent company responsible for the training of the group’s newcomers. The training centre trains apprentices for own purposes as well as for external customers.

Nowadays, 93 % of BSW’s workforce consists of skilled workers. Furthermore, it is essential to qualify young people not only to meet the skill demand, but also to overcome the aging of the workforce.