Posted on 12 Dec 2018

A steel plant always has an im pact on its environment. Envi ronmental challenges cannot be avoided, it’s just a matter of time when one has to face them. As a consequence, BSW follows a pro-active environmental strategy, fnding solutions to environmental challenges before BSW is forced to do so. In the long run, this strategy saves money and the environment.

Basic Concept

The environmental regulations for BSW are even more stringent than the already stringent German regulations. BSW elaborated over the years many concepts for the reduction of environmental impact by a steel plant. These concepts deal with the reduction of emissions to air water and soil, but also with the recycling of all by products from steel making like slag, dust, scale and some others. The success of these concepts can be seen by the very low emission values of BSW and also the proft derived from the recycling of by-products. Other ideas have been worked out to minimise noise emissions and to detect radioactive sources that are coming together with the scrap into the steel making process.

Backed by this extensive practical experience in environmental protection in the steel industry, BSE can offer these concepts and solutions to other mini-mills to shorten implementation time of environmental protection and to avoid expensive mistakes.

Emission Control

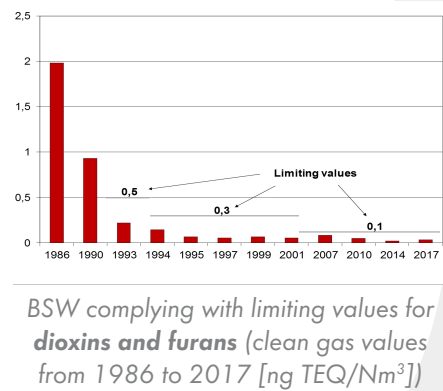

Beside continuous reduction of CO2 emissions, dust and inorganic gas, the development and installation of technology that signifcantly reduces the generation of dioxins and furans during scrap melting is one of BSW‘s prime achievements. In order to avoid regeneration during normal cooling down (de novo synthesis) the offgas is shock-cooled by a high-temperature quenching system.

Slag Recycling

BSW and its subsidiary BSW Stahl-Nebenprodukte GmbH (BSN) have been operating a slag treatment plant for about 20 years. The plant mainly consists of crushing and screening equipment to produce different slag products, differing mainly in grain size. Depending on its grain size the processed slag can be used for various purposes:

- Road construction

- Hydraulic engineering

- Construction of parking lots

- Rail construction

Selling the slag products and using the magnetic parts results in a net proft, which makes slag treatment interesting not only for environmental but also for economic reasons.

Noise Reduction

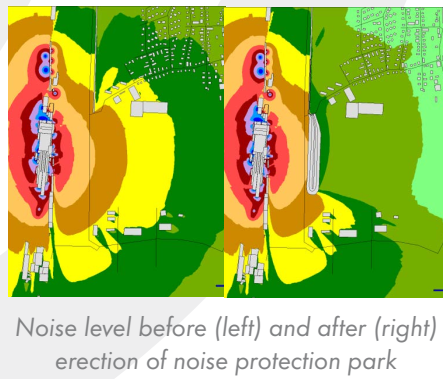

For many years BSW have been devoting special attention to noise protection and achieved an important reduction of noise pollution by taking extensive measures:

In 1976, the frst noise measurements were carried out in the vicinity of BSW, followed by noise barriers for different outdoor facilities in the 1980s and 1990s. As a next step, the furnace / casting building was insulated in 2002. The most recent measure in 2014 was the erection of a big noise protection park close to the neighbouring village. In addition, many small-scale measures are implemented continuously, in order to reach new levels of noise protection.